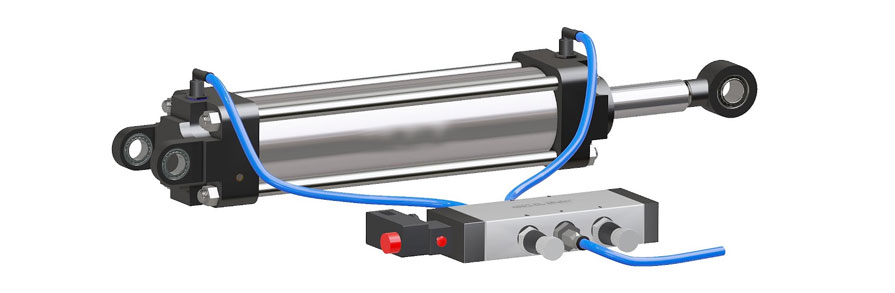

Pneumatic cylinders are mechanical devices powered by compressed air, widely used in various industrial applications for linear motion. They play a crucial role in converting the energy generated by compressed air into mechanical force, facilitating controlled movement in manufacturing and automation processes. The basic construction of a pneumatic cylinder consists of a cylindrical chamber, a piston, and a rod. When compressed air is introduced into the chamber, it pushes the piston, causing the rod to extend and perform mechanical work. Conversely, releasing the compressed air allows for retraction.

These cylinders find extensive use in applications where precise and controlled linear motion is required, such as in machinery, robotics, and industrial automation. Pneumatic cylinders are valued for their simplicity, reliability, and cost-effectiveness, making them a popular choice in various industries for tasks ranging from lifting and positioning to pushing and pulling objects. Their versatility, ease of installation, and quick response make them integral components in systems that demand efficient and dynamic movement.

Types of Pneumatic Cylinder

Pneumatic cylinders come in various types, each designed to cater to specific industrial needs. Understanding the distinctions between these types is essential for selecting the right cylinder for a particular application. Here are some common types of pneumatic cylinders:

- Compact Pneumatic Cylinders: Compact pneumatic cylinders are characterized by their space-efficient design, making them ideal for applications with limited installation space. Despite their smaller size, they deliver reliable performance and are suitable for a range of tasks.

- Double Acting Pneumatic Cylinders: Double acting pneumatic cylinders operate in both directions—extending and retracting—by using compressed air. This type provides greater flexibility in controlling linear motion, making it suitable for applications requiring precise and bidirectional movement.

- ISO AIR Pneumatic Cylinders: ISO AIR pneumatic cylinders adhere to international standards set by the International Organization for Standardization (ISO). These standardized cylinders ensure compatibility and interchangeability, simplifying the selection process for global applications.

- Round Pneumatic Cylinders: Round pneumatic cylinders feature a cylindrical shape, providing a classic and versatile design. Their construction allows for even force distribution and makes them suitable for various applications, particularly those requiring consistent and stable linear motion.

- Single Acting Pneumatic Cylinders: Single acting pneumatic cylinders operate in one direction—either extending or retracting—using compressed air. The return stroke is usually achieved through an external force, such as a spring. These cylinders are efficient for applications where one-way linear motion is sufficient.

- Tie Rod Inch Pneumatic Cylinders: Tie rod inch pneumatic cylinders are characterized by their sturdy tie rod construction, providing durability and stability. This type of cylinder is often used in heavy-duty industrial applications where robustness and reliability are critical.

Understanding the characteristics and applications of compact, double acting, ISO AIR, round, single acting, and tie rod inch pneumatic cylinders empowers professionals to choose the most suitable cylinder type for their specific industrial needs. Each type offers unique features, allowing for precise customization based on the requirements of diverse applications.

Choosing the Right Pneumatic Cylinder

Selecting the appropriate pneumatic cylinder is crucial for ensuring optimal performance and efficiency in various industrial applications. Here’s a comprehensive guide to help you make informed decisions when choosing the right pneumatic cylinder for your specific needs:

- Identify Application Requirements: Before making any decisions, clearly define the requirements of your application. Consider factors such as the type of movement needed (linear or rotary), force and speed requirements, space constraints, and environmental conditions.

- Understand Cylinder Types: Familiarize yourself with different types of pneumatic cylinders, including compact, double acting, ISO AIR, round, single acting, and tie rod inch cylinders. Each type has unique features and applications, so understanding their characteristics is essential for making the right choice.

- Evaluate Size and Space Constraints: Consider the available space for installation and the size of the cylinder needed. Compact pneumatic cylinders are suitable for applications with limited space, while larger cylinders may be necessary for heavy-duty tasks.

- Determine Operating Conditions: Assess the operating conditions of your application, including temperature, humidity, and exposure to contaminants. Ensure that the chosen pneumatic cylinder is compatible with the environmental conditions to prevent premature wear and damage.

- Specify Double Acting or Single Acting: Decide whether a double acting or single acting pneumatic cylinder is more suitable for your application. Double acting cylinders provide bidirectional movement, while single acting cylinders operate in one direction, typically with the help of an external force.

- Consider Standardization (ISO AIR): If standardization is crucial for your application, consider using ISO AIR pneumatic cylinders. These cylinders adhere to international standards, ensuring compatibility and ease of replacement.

- Evaluate Construction Materials: Pneumatic cylinders are often constructed from materials like aluminum or stainless steel. Consider the material that best suits your application, considering factors such as corrosion resistance, weight, and durability.

- Factor in Budget and Cost Efficiency: Determine your budget constraints and seek a pneumatic cylinder that offers the best balance between performance and cost efficiency. Consider the total cost of ownership, including maintenance and energy consumption.

By systematically considering these factors, you can confidently choose the right pneumatic cylinder for your application, ensuring smooth and efficient operation in your industrial processes.

Where to Source High-Quality Pneumatic Cylinder

For high-quality pneumatic cylinders, Pioneer Industries stands as a reliable and reputable source. With a proven track record in delivering precision-engineered industrial solutions, Pioneer Industries has earned a reputation for excellence. Our range of pneumatic cylinders encompasses various types, catering to diverse industrial needs.

The commitment to quality, adherence to industry standards, and dedication to customer satisfaction make Pioneer Industries a preferred choice for businesses seeking top-notch pneumatic cylinders. When you source from Pioneer Industries, you can expect not only superior products but also comprehensive support and service. Choose Pioneer Industries as your trusted partner for high-performance pneumatic cylinders, ensuring efficiency and reliability in your industrial applications. Contact Us Today!